5 Advantages of Using Gravity Conveyor Systems

Gravity Conveyor Systems are a type of equipment that moves materials from one place to another without the need for external power sources. These machines’ simplicity and efficient design make them one of the most popular choices for many businesses. Here are five advantages of using Gravity Conveyor Systems in your business:

1. Easy to Use

One of the benefits of the Gravity Conveyor System is that it's easy to use. With its simple design, it requires no additional power source or complex controls to manage. All you have to do is load or place materials on the conveyor, and gravity takes care of the rest. It's ideal for businesses looking for an affordable and easy-to-use conveyor system, whether for short or long distances.

2. Low Maintenance

Gravity Conveyor Systems require minimal maintenance, making them an economical choice for businesses that want to save time and money. These machines don't require regular upkeep, unlike power-driven conveyors that rely on motors, gears, and controls that are prone to wear and tear. Hence, SmartConvey gravity conveyor systems need little to no maintenance, which means fewer downtimes and less maintenance expenses.

3. High Safety

Safety is essential in any workplace, and the Gravity Conveyor System is a safe and secure way of moving materials. The materials move slowly on inclined surfaces without the need for motorized assistance, preventing mishaps, such as collisions, entanglements, and falls. , Gravity Conveyor Systems have built-in safety features, like emergency stop buttons, locking mechanisms, and air brakes, ensuring safe operations and minimal risk of damage.

4. High quality

The quality of the materials that go into constructing a Gravity Conveyor System is a testament to their durability and longevity. These conveyors are built to withstand the weight of even the heaviest materials and can last for years with minimal maintenance. The frame, rollers, supports, and other components are made of high-quality materials that can withstand harsh environments and heavy usage, ensuring that your business can rely on a Gravity Conveyor System for all its material handling needs.

5. Versatile Application

A Gravity Conveyor System is versatile in its application. It can transport various materials, shapes, and sizes without difficulty. Materials such as food, chemicals, furniture, and electronics can be easily transported using Gravity Conveyor Systems. They're adable, allowing businesses to change how they're used to accommodate new materials or deal with unique processing requirements.

Gravity Conveyor Systems are easy to use, require minimal maintenance, and transport materials precisely and safely. Here are three simple steps to using Gravity Conveyor Systems:

1. Placement

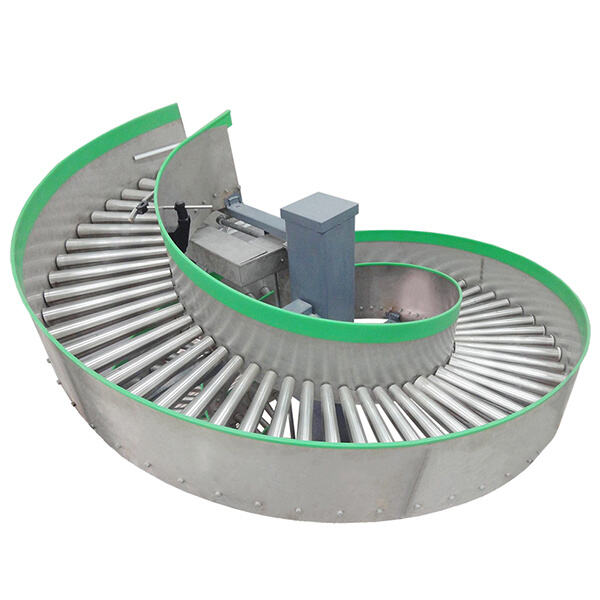

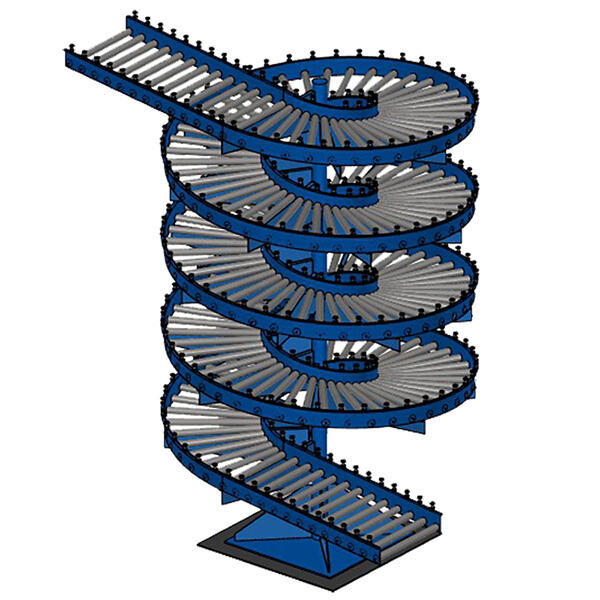

Determine where to place the Gravity Conveyor System in your facility. These machines can be used in a wide range of industries; therefore, you must identify which materials you'll be moving, where they're coming from, and where they're going. You must also decide if your conveyor will be a straight chute or a spiral in design.

2. Loading

After determining the distance and the type of conveyor required, you can load the materials onto the loading conveyor systems. Ensure that the materials are placed and distributed evenly on the conveyor upfront. The weight of the materials will move the conveyor along the right path, and the slow speed will ensure safe and precise transportation.

3. Monitoring

Always monitor the SmartConvey Gravity Conveyor System's performance during operation. Check if the materials are moving smoothly and if there's any obstruction in their path. Observe the conveyor's movement, and ensure that it's following the path you require. If you find any issues, identify them, troubleshoot, and fix them immediately to avoid future downtime.

Gravity Conveyor Systems are reliable, cost-effective, and can last for years with minimal maintenance. However, like any other equipment, their performance depends on the quality of service they receive. Consistent and proper maintenance is crucial to prevent downtime and keep the conveyor in tip-top condition. Here are three ways you can get quality service for your Gravity Conveyor Systems:

1. Routine Maintenance

Gravity Conveyor Systems are low maintenance; however, to keep their performance at its best, you need to conduct routine maintenance. Check the rollers and frames for damage, clean off any accumulated dirt, ensure belts and drives are free from dust and debris, and confirm the system’s levelness. These actions can prevent material buildup and equipment malfunctions that can lead to downtime.

2. Replacement Parts

Gravity Conveyor Systems have moving parts that wear out eventually. When you find damaged or worn-out parts, replace them promptly with original spares from authorized dealers. These help to ensure the machine's safety, performance, longevity, and reduce the cost of maintenance.

3. Consulting with Experts

There are qualified technicians and engineers who can inspect and service your SmartConvey gravity assembly conveyor systems from time to time. Their expertise will help identify any problems and provide prompt solutions. They can design maintenance schedules that suit your business's need, provide repair services and suggest improvements to the conveyor's performance.

Gravity Conveyor Systems have been in use for years, and technological advancements have played a role in new designs and their enhanced features. Here are three exciting innovations in Gravity Conveyor Systems:

1. Adable Height

The current models have adable conveyor heights, allowing businesses to customize their conveyor systems to specific requirements. This feature is ideal for businesses that need to move materials between work levels. It saves time and minimizes material handling by using gravity to do most of the work.

Integration with Robotics

Some companies have integrated SmartConvey gravity powered conveyor systems with robotics to create automated assembly lines. This innovation reduces the need for human labor and improves efficiency while minimizing safety concerns. These systems move materials from one station to another, and manufacturing robots can pick and place the products onto the conveyor for further processing.

2. Customization Options

Advancements in the manufacturing of Gravity Conveyor Systems have given businesses the option to customize their conveyors to their requirements. Manufacturers now offer customizable rollers, frames, and supports to fit unique business needs. Customized conveyors increase the flexibility of the systems, enabling companies to handle materials efficiently, safely, and inexpensively.

Gravity Conveyor Systems are a cost-effective, easy-to-use, low-maintenance, and safe way of moving materials. These technological innovations in SmartConvey Gravity Conveyor Systems have improved their performance, safety features, customization options, and increased versatility in applications. To ensure maximum system performance, choose quality service providers, use it as recommended, and embrace these improvements in automation technology. With all these benefits, incorporating Gravity Conveyor Systems in your business can significantly improve your operations and your bottom line.

We a fully integrated firm combines R D, Design sales, Service, Research. Our engineering team Gravity conveyor systemsto providing high-quality technical support. They also support continuous development of research and efforts develop innovative solutions.

We leading company China that creates, produces, delivers high-quality conveyors systems across the globe. able to provide flexibility OEM as well as ODM Gravity conveyor systems. You customize products to suit your specifications and needs.

In pursuit of R D for automated sorting systems, conveyor systems, have extensive and professional Gravity conveyor systemsthese areas. We'll deliver order when it is scheduled, because understand how crucial it is to keep business running smoothly.

business has Gravity conveyor systemsexperienced team of experts foreign trade. They have over 10 years expertise foreign trade and knowledgeable about all aspects foreign trade and international trade practices ensure seamless communication and effective transactions.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy