Factories can benefit a lot from Plastic bottle conveyor systems They help to shift bottles from place to another in a very short time-some with ease and comfort. These systems are a combination of belts and various machines that cooperate together to carry the bottles without any hindrance. So, here we are going to discuss about how different factories takes advantage of plastic bottle conveyor systems in so many ways.

Conveyor systems are an essentially important part of how factories operate, the same is true for plastic bottle conveyor systems. They make processes work so that factories can quicker produce more products. With a conveyor system established in any factory, workers can then focus on the more essential work while the bottles are moved and carried along automatically by the conveyor. This not only saves you the time (which is as valuable if no more) and also helps streamline & organize your overall production process.

The environmental benefits of a plastic bottle conveyor system are also enormous. Conveyor systems make more sense due to the fact that they use lighter and far easier methods than relying on heavy machinery like forklifts to move bottles around. This translates into reduced energy requirements for them to operate, and this reduces the carbon footprint from the factory. Factories sustainably reduce their energy consumption using conveyor systems, helping to keep our planet safe.

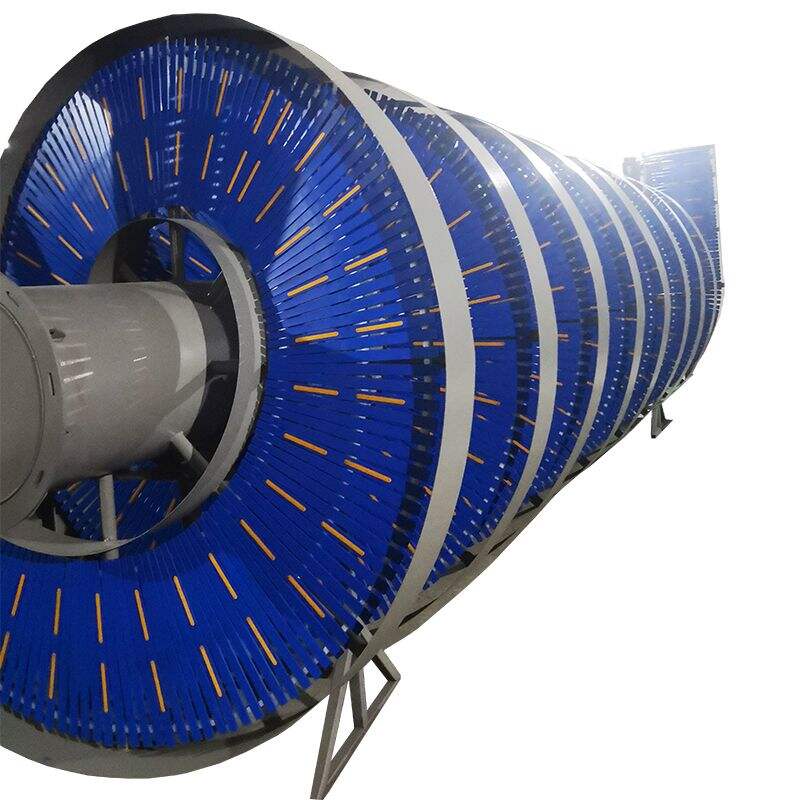

There are many different types of bottles that a plastic bottle conveyor systems will be able to handle. They can self-adjust to move all types of bottles with different shapes, sizes and materials. This can make them very handy for factories that contain numerous various kinds of bottles. Whatever the size, plastic bottle conveyor systems can take on — from small bottles to larger containers proving their worth for various businesses.

Apart from enhancing the performance they also ensure of safety for workers with plastic bottle conveyor systems. Given employees are now handling these bottles manually, there is a danger of getting hurt. Would they be straining their backs or even damaging a finger trying to lift such heavy bottles. In case of conveyor systems, the risks are much smaller because that way bottles will move automatically. Workers do not have to lift heavy items, thus a lesser risk of injury.

With growing automation in factories, it is more likely that conveyor systems for plastic bottles will remain a necessity. They will be developed further, enhanced and become much better by enabling companies to generate more products in a lesser time span with reduced energy. This is an important advancement helping companies to become more competitive in the market and taking care of its environmental footprint.

business has plastic bottle conveyor systemsexperienced team of experts foreign trade. They have over 10 years expertise foreign trade and knowledgeable about all aspects foreign trade and international trade practices ensure seamless communication and effective transactions.

Committed the R D of intelligent sorting systems, conveyor systems, have plastic bottle conveyor systemsextensive knowledge in these fields. We'll ship order on time because we understand how important it is ensure that your business runs smoothly.

are a full-service company which combines R D Design plastic bottle conveyor systems, Service, R D. engineers are committed providing top-quality technical support. They also support ongoing research and development efforts to develop innovative solutions.

We top company in China designs, produces sells top-quality conveyor systems throughout world. flexible OEM as well ODM service accessible you. Make products custom-designed plastic bottle conveyor systemsyour requirements and needs.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy