If you consider Installing conveyor system to your industry If you do, then note that it is normal for individuals like yourself to think of the many things they can use in order to determine which among them really is superior compared to the rest. Don’t worry. We are here to help you. Here are some tips that you will find useful in selecting the corrugated cardboard intelligent conveyor system to meet your business requirements.

When You Would Need a Corrugated Cardboard Conveyor

So, before we dive into the benefits of using corrugated cardboard conveyor belt systems by SmartConvey for your warehouse or storehouse operation. Let us discuss first the why you should return and invest in this kind system : These are intelligent and effective systems. They utilize cutting edge methods of using sensors and automation which can deliver the materials precisely within Ashford but yet faster. This can be of great help for your production line. It is better for the environment and your business to produce less waste, as well when you move materials effectively. Secondly, corrugated cardboard is sustainable. Recycling it is easy, so businesses can be more sustainable and environmentally conscious choosing.

Considerations When Choosing a Conveyor System

This means you have to consider a lot of important things when selecting the conveyor system. You should first take into calculation the dimensions and weight of all items need to be moved. You need to make sure the Conveyor System were not destroy your material and slow down production. If you have extremely large or heavy items, this shows as well that the cardboard conveyor needs to be one of great strength.

The next thing to consider is the layout of your production line and where will you fit that conveyor. For instance, do you need to move materials up and down in addition to side-to-side? Will you have switch directions a lot or transfer trains lines? You will find a number of conveyor belt layouts available on the market, when you go to buy one for the industry. But it is not always possible that every design can work well along with your complete production process as required by diversified business purposes; A very important thing would be rather select what works best using their creation styles and kinds Etcersonally.

Tailoring Your Conveyor System to Suit your Business

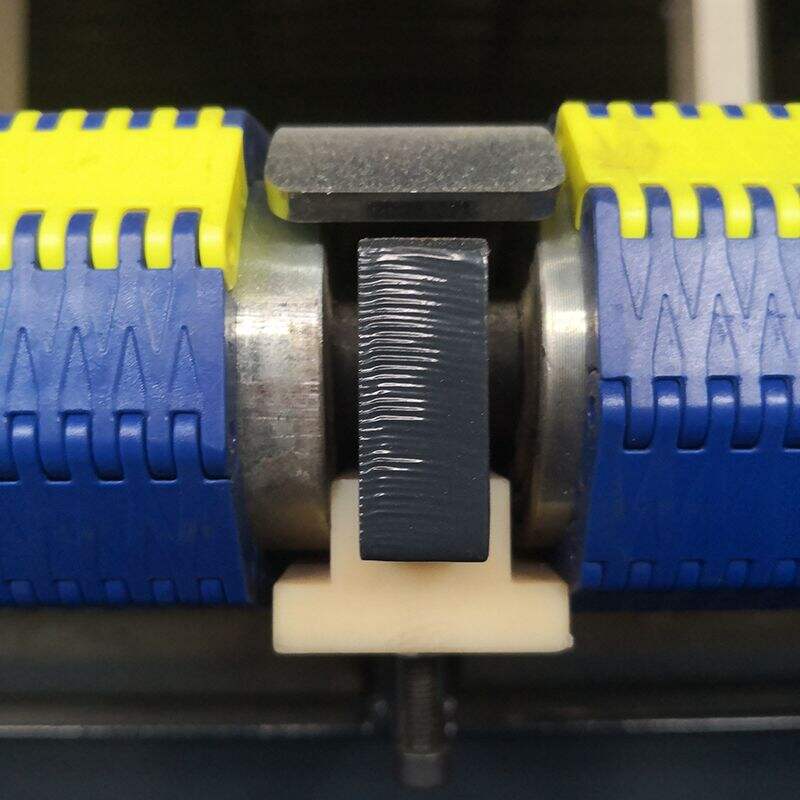

Making sure that every conveyor system is custom-designed to your unique business needs. By partnering with a manufacturer, you can develop an adapted conveyor system for your facility and materials to be carried. They can assist you in reviewing your production questions and planning for the best way to realize it. Available options may include selecting conveyors such as belt, roller or chain type. You might even want to consider integrating things like sensors and automated controls that can help take your conveyor belt cardboard system a step further in terms of efficiency.

Conveyor Technology News

Conveyor technology is constantly changing and becoming better. This is one the reason why it is vital to stay ahead with new releases and technology. Newer conveyor systems like those that incorporate artificial intelligence (AI) and machine learning can help optimize the way materials are moved to minimize waste. Augmented reality might take the form in other systems such as apps to help workers locate materials on site or for troubleshooting issues that occur during production. This means that in order to make an informed decision which helps your business grow, you want to be on the cusp of these (and many new) trends and technologies.

How to Keep Your Conveyor in Good Shape

Once you have selected and received your new conveyor system, the most important step is to make sure that it works correctly. Routine maintenance and cleaning are critical because they can help to prevent failures, promote appliance reliability for example decode (to an extent) solutions. This is also the stage where you could start adding sensors or other monitoring tools that notify you of any issues before they turn into real problems. This preventive strategy can end up saving you time and cash in the long term.

Finally, picking the right line of powered roller conveyor systems for your needs can feel a daunting task; but nevertheless it certainly pays off. Taking the time to think through your material handling needs, production goals and how this all fits together can be extremely beneficial when designing a conveyor system optimized for improving productivity on your assembly line. In addition, staying updated with new improvements in conveyor technology guarantees that your system operates efficiently and keeps business running for years.