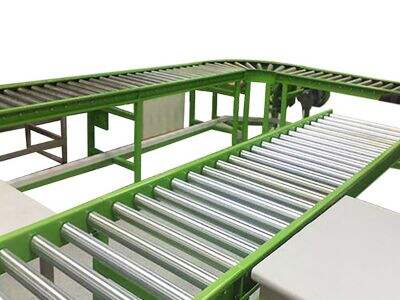

Roller conveyors, the magical carpet that transports goods from one place to another as if by magic. They provide crucial advantage in various sectors that help quick and efficient working. Think of it as a roller coaster, but one that transports boxes, bags, or any other items instead of people. Like with roller coasters that are made to entertain, not all roller conveyors need to be made from the same materials for every job., we will dissect some of the most common high friction environments here in this guide so you can get an idea how material spec handy work together.

The Necessity for High Friction Roller Conveyor Materials:

Roller conveyors involve bulky loads and they are subject to most of rubbing and sliding when things move fast. When it comes to high-friction environments, the surfaces rubbing together must stand up to repeated friction and pushing without wearing out too quickly. Choosing the right material: This is an important aspect that goes into making a pallet conveyor system and it ensures that the system works smoothly for a long time before there is any breakdown.

Selecting the best flexible material for high-friction environments for maximum performance:

SmartConvey understands the need for high-friction material in roller conveyors Various materials have various characteristics that can impact the functionality of a roller conveyor. For instance, rubber is a frequent material utilized because of its retainment and energy. Nevertheless, in high friction environments such as these, it might instead be more efficient to utilize polyurethane or even high density plastics materials able to handle the hard conditions. So, choose the right material and your roller conveyor will run problem-free even in extreme surroundings.

Benefits of Special Materials for Roller Conveyors:

There are several benefits you can enjoy by using specialized materials in your roller conveyors. They are made to be durable for high friction which reduces wear and tear and thus enhancing performance. They also assist in noise reduction, productivity increase, and the safety of the worker. Specialized materials to match your roller conveyors The benefit of investing in the best materials when it comes to your conveyor gravity is that you can avoid repair needs and replacements further down the line, saving money.

Material Options for High-Friction Roller Conveyors Comparisons:

These High-Friction Roller Conveyors Made Of Every material has its inherent properties, and the material used can have numerous options available for high-friction roller conveyors. While some material applications are better for heavy-duty, others may be suited for light duty. They should be compared to find one that best meets your requirements. SmartConvey can supply roller conveyor modular belt with a choice of materials to suit all needs, so you will be able to find what you need for the job.

In high-friction environments with the right roller conveyor material specs that can maximize efficiency and longevity:

Roller conveyors are used in high friction environments to reduce turning force, advanced polymer materials are found in most roller bearings as well as some open frame rollers. Protect your roller conveyor with high quality materials that will keep it running in top conditions, even when things get rough. By choosing the proper material specifications you can extend the life of your roller conveyor, lower maintenance costs and increase productivity throughput.

Ultimately, selecting the perfect material for roller conveyors in high-friction environments makes all the difference between a smoothly running system that lasts ages and one which must be replaced frequently due to excessive wear. Knowing that you require specialized materials, researching your options, and picking the right material specs will help you remain efficient for the long haul. For the ultimate solution in materials, trust no further than SmartConvey for all your roller conveyor needs.

Table of Contents

- The Necessity for High Friction Roller Conveyor Materials:

- Selecting the best flexible material for high-friction environments for maximum performance:

- Benefits of Special Materials for Roller Conveyors:

- Material Options for High-Friction Roller Conveyors Comparisons:

- In high-friction environments with the right roller conveyor material specs that can maximize efficiency and longevity: