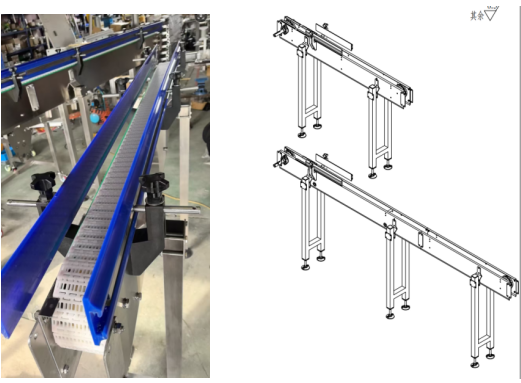

1.Products Pictures and Drawings

Conveying Products: 330ml Cans

2. Applications and Features

We design this conveyor to convey the 330ml cans. The cans temperature is around 40 celsius degree. We help cans conveying from filling area to packaging areas.

This modular belt conveyor feature is having more stable and flat conveying process than the plastic chains conveyors.

3. Conveyor Technical Datas

| No. | Technical Date | Dimensions |

| 1 | Conveyor Effective Width | 90mm |

| 2 | Conveyor Belt Type | Flush Grid Modular Belt, White Color |

| 3 | Conveyor Height | From 300mm to 1300mm |

| 4 | Conveyor Side Guide | Stainless Steel Profile+PE Height:80mm |

| 5 | Conveyor Frame | Stainless Steel |

| 6 | Conveyor Axis | 30mm |

| 7 | Motor | Without Motor (Customer Provided) |

| 8 | Additional Parts | With Drain Grooves avaialble |

4.Blog Titles

1. Why 90mm Width Straight Modular Belt Conveyors Are Ideal for Your Production Line

2. The Advantages of 85mm Modular Belt Conveyors for Efficient Material Handling

3. Choosing the Right Conveyor for 330ml Cans: Key Considerations and Benefits

4. Optimizing Your Conveyor System: The Power of 85mm Straight Modular Belts

5. Choosing the Right Conveyor: Benefits of 85mm Width Straight Modular Belts Conveyor

6. Packaging Line Flexibility: The Versatility of Straight Modular Belt Conveyors

7. How Modular Belt Conveyors Revolutionize Coca-Cola’s Bottling Process

8. Why Modular Belt Conveyors are Ideal for 330ml Can Transport

9. the role of modular belt conveyors in improving Coca-Cola's production, bottling, packaging, and logistics processes

10. "Modular Belt Conveyor vs Plastic Chain Conveyor: Which is Right for Your Production Line?"

11. The Best Conveyor Systems for Handling 330ml Cans in Beverage Factories

12. The Ultimate Conveyor Showdown: Modular Belts vs. Plastic Chains in Industrial Applications

13. Flexibility and Efficiency: The Power of Accumulation Conveyors for Cans

14. Streamlining Your Canning Line with Modular Belt Accumulation Conveyors

15. How Flexible Accumulation Conveyors Improve Can Handling and Sorting Efficiency

16. What kind of packages types that modular belt conveyor could handle?

17. Key components of a Cans Conveyor Divert System

18. Types of Bottle and Can Conveyors: Specifically designed to handle bottles, cans, and glass containers of various sizes.

19. Handling of different cans types

20. Applications of 330ml Can Conveyors

5. Key words

330ml cans packaging conveyors

Canning line conveyor for 330ml cans

330ml beverage cans handling conveyor

Reliable 330ml can packaging conveyor

Modular belt conveyor

Straight conveyors

Straight modular belt conveyors

Drinks conveyors

Conveyors for cans packaging lines

Straight modular belt conveyor for cans

Modular belt conveyor for canning lines

Straight-line conveyor for can production

Modular belt conveyor system for beverage can production

light-duty modular belt conveyor for cans

Cans packaging conveyor with modular belt

Cans filling and packaging line

Robotic cans packaging line

Complete beverage canning lines

Can packaging and sorting line

End-of-line cans packaging system

Canning line automation

Cans accumulation conveyor

Flexible accumulation conveyor for cans

High-capacity cans accumulation conveyor

Modular accumulation conveyor for cans

Cans flow control and accumulation conveyor

Conveyor system for can accumulation

Accumulation conveyor for beverage cans

Cans conveyor divert system

Cans diverter conveyor

Cans conveyor with automated diversion

Conveyor for diverting cans to multiple lines

Cans diversion and distribution conveyor

Efficient cans divert system for packaging lines

330ml Cans transfer and divert conveyor

Cans flow divert system

Bottles conveyors

Bottling Conveyors

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy