Motorised Roller Conveyor Re-Simplifies Handling of Heavy Goods

Are you a heavyweight mover who just wants to get rid of the Hazzard in moving stuff around from one place using then leave it at your disposal. If this is the case then a motorised roller conveyor could be just what you need! We will even cover how this new tool works in detail, show you best practices on using the functionality safely and efficiently....

Motorised roller conveyor would be ideal, should you be a business that shifts heavy goods such as bags of coffee. Standard conveyors are manual, but with the motor roller conveyor it is an effect of its mechanical engine. Not to mention reducing the secondary manual labor injury risk... and giving plenty more time, as well as muscles upfront.

This motorized roller conveyor is really going to shake up with the way things move! It improves productivity and lower labor costs by removing the needs of human workers. By combining with sensors (they can recognize an object on the conveyor and automatically push it off while running, leaving no energy to waste) it only becomes higher.

Safety Features Of The Motorised Roller Conveyor

The motorised roller conveyor is provided with the protection level as much high to work CONTRAC. The most basic of which would be the emergency stop button, which could be used to shut down all conveyor (or ends as is this case) in an event that a dangerous state has been reached. There are sensors that can see units and will not allow the conveyor to move.

Motorised rollers conveyors can be used at/for:

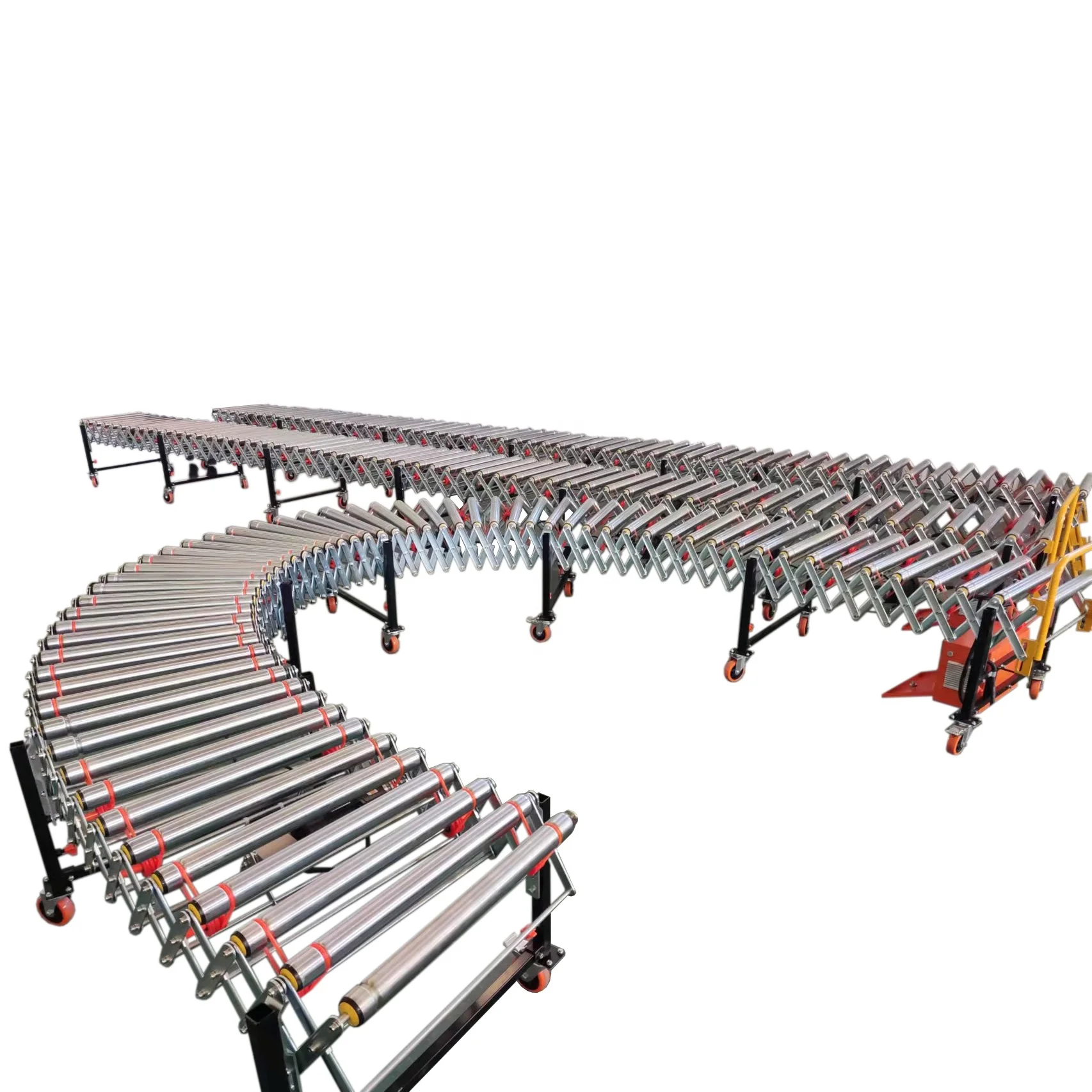

The motorised roller conveyor is perfect for a variety of applications and could move the heaviest boxes, crates or pallets around your warehouse or distribution centre in painless silence. Due to its versatility, titanium is a highly useful material for many sectors.

The motorized roller conveyor very simple in nature. Simply turn the conveyor on, put your speed freely available and each product onto the transport strip to make it work for you. It is essential that the items on the conveyer be aligned properly for transport.isdir.sep.archive=trueWords: 116

As with any machine, regular upkeep and maintenance are necessary for the motorised roller conveyor in order to keep it running smoothly. This can include cleaning conveyor belts and motors, as well other signs of wear. Maintain conveyor equipment as recommended by manufacturer and conduct annual servicing on the conveying unit.

Committed the R D of sophisticated motorised roller conveyorsystems conveyor systems, and other conveyors, we have a wealth of extensive knowledge in these fields. We can assure you that we will make sure your order is delivered on time because understand importance of delivering your order on time and ensuring your business runs smoothly.

company is run by skilled team foreign trade professionals. foreign trade team more than 10 years of experience is well versed on all aspects motorised roller conveyor trade.

We an integrated business R D designs sales, service R D. team of engineers is dedicated to providing professional technical support. They also encourage continuous motorised roller conveyorof research efforts come up with creative solutions.

We leading company China that creates, produces, delivers high-quality conveyors systems across the globe. able to provide flexibility OEM as well as ODM motorised roller conveyor. You customize products to suit your specifications and needs.

In the world of machinery, quality counts for everything and it is something that a motorised roller conveyor performs very well in helping you achieve. (durable conveyor belts and a powerful motor that provides both efficiency circularity making this one of workflows most reliable) Handle intense weight, without slowing down. From a safety perspective it seems that emergency stop buttons and sensors account for the human using them to be safe first.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy