Have you ever wondered how companies move their products from one place to another in their warehouse or factory? The answer is by using a powered roller conveyor. This amazing invention has revolutionized the way businesses transport their items. We will explore the advantages, innovation, safety, use, how to use, service, quality, and application of SmartConvey portable roller conveyor.

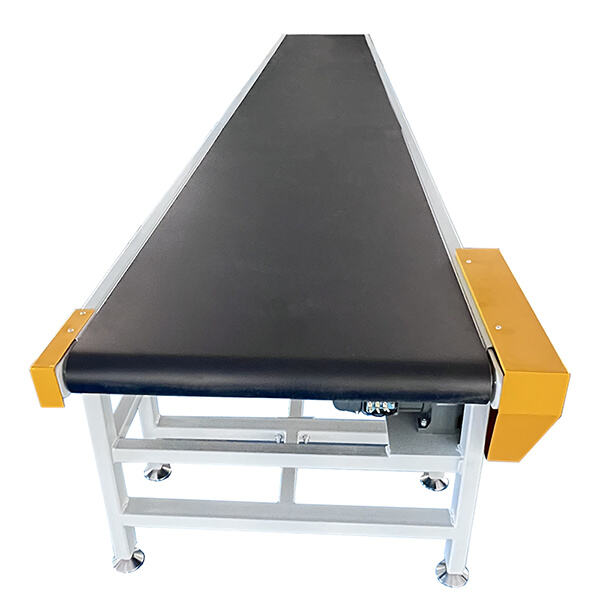

The powered roller conveyor is a game-changer for businesses, especially those that deal with heavy and bulky items. It increases the speed and productivity of moving items compared to manual labor. It can handle a wide range of items, from small packages to large pallets. Companies can customize the length, width, and height to fit their specific warehouse needs. This SmartConvey flexible roller conveyor reduces employee fatigue and enhances the safety of moving items, which translates to increased employee satisfaction and a lower rate of workplace accidents.

The powered roller conveyor is an innovation in the material handling industry. Manufacturers now offer a vast array of features that cater to specific industries. SmartConvey power roller conveyor system has sensors that detect packages and adjust their speed, leading to a more efficient workflow. Other conveyors have LED lights that indicate a package's location, which is particularly helpful in dimly lit warehouses. Innovative technologies such as automated guided vehicles (AGVs) and robotics now work hand-in-hand with roller conveyors to create a fully automated and intelligent material handling system.

Safety is a top priority in workplaces that use powered roller conveyors. Manufacturers ensure that their conveyors adhere to safety standards set by regulating bodies. The design of SmartConvey retractable belt conveyor often includes guardrails and emergency stop buttons to prevent accidents. Companies must train their employees on how to use the conveyors safely, eliminate any obstructions or debris, and enforce strict rules to prevent horseplay and reckless behavior.

We a fully integrated firm combines R D, Design sales, Service, Research. Our engineering team powered roller conveyorto providing high-quality technical support. They also support continuous development of research and efforts develop innovative solutions.

We leading company China that creates, produces, delivers high-quality conveyors systems across the globe. able to provide flexibility OEM as well as ODM powered roller conveyor. You customize products to suit your specifications and needs.

We committed research and powered roller conveyorof intelligent sorting systems, conveyor systems, have rich and extensive experience these fields. We'll ship your order according to time frame you have set because we know importance of it to keep your business running smoothly.

company staffed by a highly skilled team foreign trade powered roller conveyor. They have over 10 years working in the field foreign trade. They proficient in the entire process international foreign trade procedures to ensure smooth communications and smooth transactions.

Using a powered roller conveyor is straightforward. The conveyor consists of rollers, bearings, and a motor that powers them. When the motor runs, it drives the rollers, allowing them to move the items placed on top of them. To use the SmartConvey expandable roller conveyor, the employee must place the item on one end of the conveyor and let it roll towards the other end. Businesses use these conveyors for various applications, from loading and unloading trucks to sorting and packaging items.

Before using the powered roller conveyor, employees must familiarize themselves with the machine and learn how it operates. They must wear proper personal protective equipment (PPE), such as gloves, safety shoes, and helmets, to avoid getting injured. They should also inspect the SmartConvey stainless roller conveyor for any damages or loose parts before use. Employees must switch off the conveyor before attempting any maintenance, such as cleaning or lubricating the rollers.

Companies that use powered roller conveyors must ensure that they are well-maintained to extend their lifespan and prevent costly breakdowns. Manufacturers offer a range of services, such as regular maintenance, repair and replacement of parts, and upgrades. Businesses must schedule regular cleaning and maintenance to prevent dirt, dust, and debris from clogging up the SmartConvey motorised roller conveyor. They should also lubricate the rollers regularly to enhance their efficiency.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy