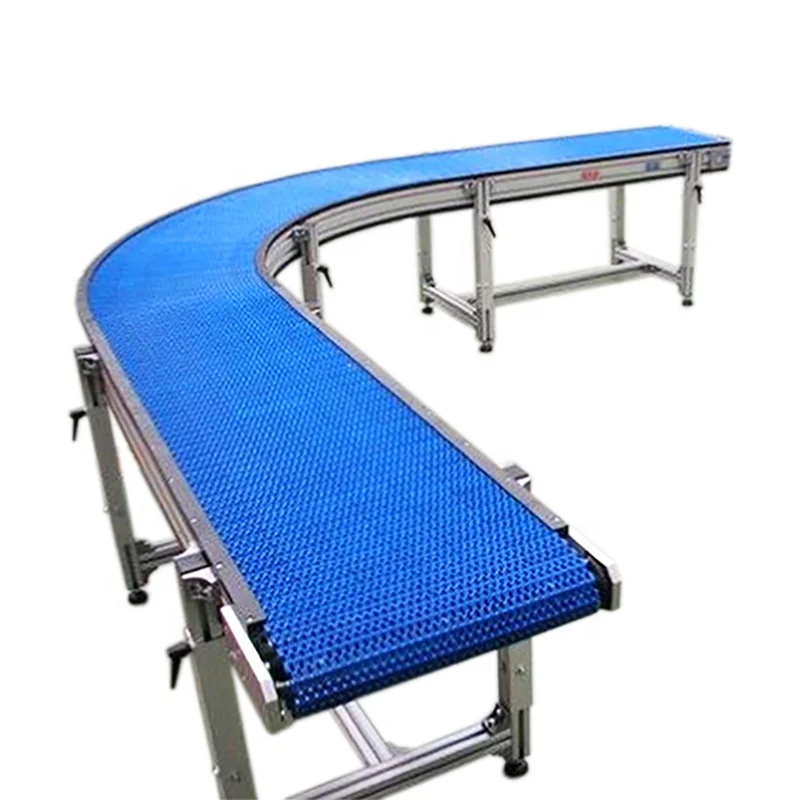

Roller Curve Conveyor: The Ultimate Secure and Surefire Solution for conveyor systemIn the contemporary world of manufacturing, efficient production lines that are also entirely safe to use is a basic necessity needed by organisations intending large costs. Roller Curve Conveyors: A Benefit to Current Manufacturing Processes While sorting conveyors seem more expensive than conventional systems, their benefits are well worth the cost difference; placing productivity and security ahead of price for a long-term investment. This article will delve into the modern roller curve conveyor and how they can increase efficiency in your business.

Key Benefits of Roller Curve Conveyor

Traditional conveyor systems are not necessarily belt conveyors, and roller curve conveyors have many advantages over traditional ones. Perhaps the most important benefit of all is their adaptability, enabling businesses to tailor the arrangement on their production line around their own requirements. Easily integrate roller curve conveyors with your existing conveyor system, or start fresh like a business that is growing rapidly. Roller curve conveyors have the added benefit of being able to move products rapidly. Rollers move items smoothly along the conveyor and help reduce jams which can stop or slow down production. Roller curve conveyors can be made to have a very small footprint, which is great when you are working with limited space.

The method of moving products along the production line using roller curve conveyors is an advanced technological phenomenon. A motor is what causes the rollers that run on this conveyor system to move in a smooth and consistent manner. These are ideal for use on heavy and lightweight items all in one! After all, roller curve conveyors are unique in that they can transport items of different shapes and sizes. The rollers are changeable so they can be adapted to different product sizes. This helps in the smooth transfer of all types of courier from small boxes to very large and gad-and-bulky items.

Regardless of what is on your production line, safety should be top priority. Roller curve conveyors are completely safety oriented units to avoid accidents and injuries. The rollers are covered to protect workers from catching their hands in the belt. Shift-Eject buttons are also installed on the conveyor system so that, in case of any emergency, the Shift can be halted very swiftly. Also, roller curve conveyor is built to considerably reduce noise levels so that a user can work in an environment where they do not have stress. It operates silently, which makes it non-distracting and helps to maintain high levels of concentration resulting in greater safety.

A roller curve conveyors are the most vital tool for production, packaging and distribution industries. These are suitable for businesses that have to load their products with a great pace and efficiency from one place of production line to another. The roller curve conveyors can also be combined with other conveyor systems (eg straight) to build a complete production line.

Roller curve conveyors are somewhat easy to use. First off, to help normalize conveyor safety features and make them operational include that a business installs the system properly. The products are then placed on the conveyor belt and carried along the production line by use of rollers. The conveyor speed can be tailored to the businesses requirements.

Service and Quality

For businesses, the service provided by conveyor system is of great significance as well. The roller curve conveyors are designed and produced in accordance to the highest quality standards. Business grade projectors are built to last and their maintenance cost is minimal, thus an excellent investment for any business. But roller curve conveyors offer wonderful customer service as well. With the way that technical support at production line conveyor manufacturers works, you can count on help from their team immediately should any problems arise with or concerns about the system. It provided lifetime lubricated bearings that are maintenance free to ensure the conveyor system remained in peak working order, resulting in improved productivity with minimal downtime.

We an integrated business R D designs sales, service R D. team of engineers is dedicated to providing professional technical support. They also encourage continuous Roller curve conveyorof research efforts come up with creative solutions.

have years experience in field and are dedicated research and development intelligent sorting systems and Roller curve conveyorsystems. will deliver your order on time because we understand how crucial it is to ensure your company runs smoothly.

We are renowned company China that creates, produces supplies high-quality conveyor systems across globe. flexible OEM as well as ODM service available you. You can modify products according own Roller curve conveyorpreferences.

business has Roller curve conveyorexperienced team of experts foreign trade. They have over 10 years expertise foreign trade and knowledgeable about all aspects foreign trade and international trade practices ensure seamless communication and effective transactions.

As a part of the robust system, roller curve conveyors are an integral element in advanced production lines. Featuring several benefits over traditional conveyor systems, these include improved productivity and safety as well as greater flexibility. Single or Multi-StrandPresser Roller curve conveyors are constructed with the aid of cutting-edge technology, making them more versatile and ideal for a variety of applications. A type of equipment that every manufacturing company needs, Roller Curve Conveyors are helpful in so many ways- improve their production lines and reduce downtime thereby increasing profitability.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy