Ever wondered how extremely heavy boxes or bags are lifted from one height to another in places like factories or warehouses? This is pretty cool, though-spiral conveyor being the trendy mode. So, we are about to tell you a bit more on why spiral conveyors works so well and how they contribute in the long-term aspect of safety gear; what are some applications for which these technology can be certainly used and finally few best practices that should be followed while using them - in order not stressing any motor un-necessarily.

Benefits of a Spiral Conveyor Design

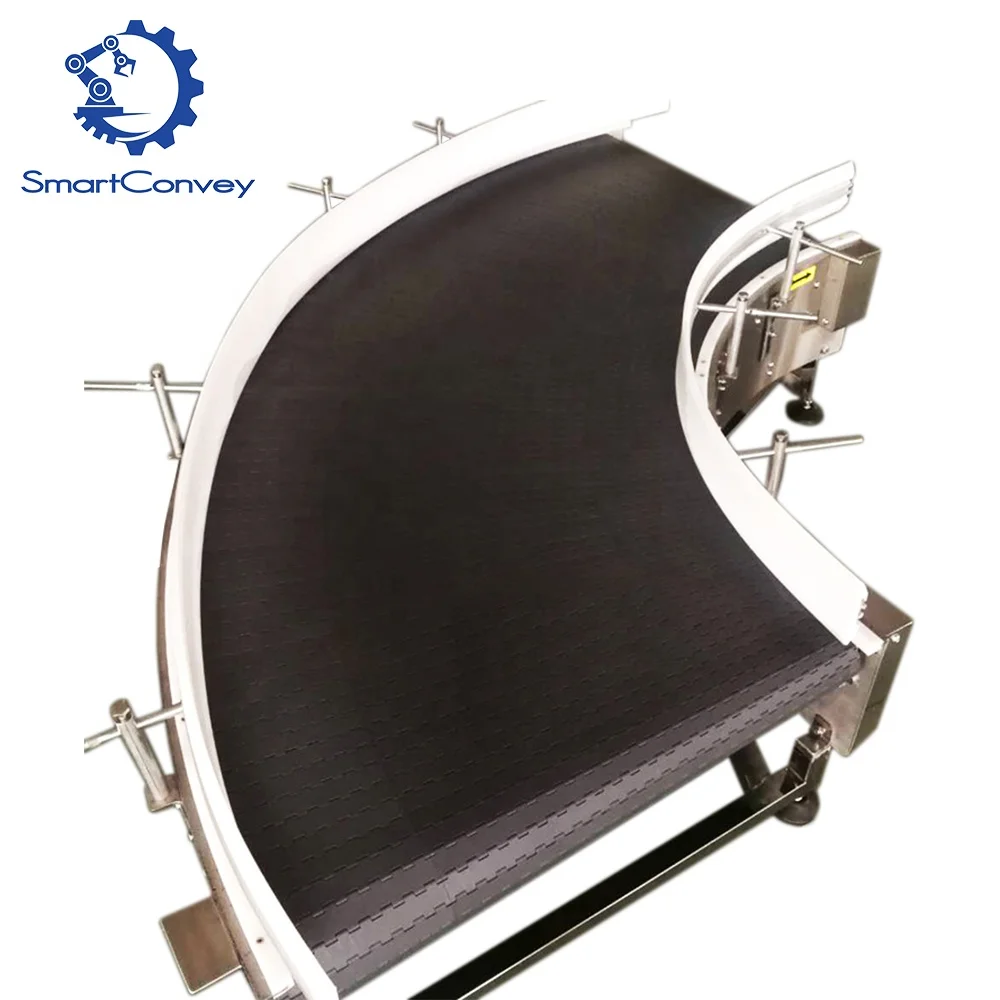

The great thing about spiral conveyor design is that it can move things up or to the side all in a very compact footprint. These conveyors are made to keep things moving without any downtime and no need for labor. They are a favorite of many factories and warehouses because they can quickly, safely, and efficiently move goods.

In response, the design of spiral conveyors has had a good leap forward in recent technological advances to increase efficiency and safety. For example, special plastic chain belts and VFDs (variable frequency drives) in combination with dynamic braking systems allow items to travel up inclines or around curves in a gentle fashion without material damage. In addition, some machines have sensor to detect an jam or misalignments in the conveyor and avoid stoppages on account of it.

Conveyor system safetySafety is one of the critical things when it comes to a conveyor. But every day in most factories, employees need to get close and personal with spiral conveyors. That's why safety systems, including guardrails,emergency stops and interlocks have been added to protect the workers in case of failure. It is also important to train employees in the proper use and maintenance of spiral conveyors so as not to cause accidents.

For the most part, running a spiral conveyor is pretty simple. Items are loaded at one end of the conveyor and transported to be conveyed upwards, over a curve then back downwards towards the other end. It consists of an electric motor that runs the conveyor belt or chain, making possible to lift up and down commodities. It is critical that nothing tips or falls, meaning the product must sit centered on a belt conveyor.

Just like any piece of equipment, spiral conveyors require regular service and maintenance in order to operate as efficiently for a long time. This machine requires routine inspections, adequate lubrication and when necessary timely replacement of belts on chains in order to function at its full capacity. Because there are so many different spiral conveyor brands and manufacturers to choose from, it is important that you select a model of high quality suitable for the durability, reliability and safety necessary in your production processes.

are prominent company China that creates, produces distributes high-quality conveyors systems throughout the world. able to provide our Spiral conveyor designof OEM as well as ODM services. You can tailor the products according unique requirements and preferences.

business has highly experienced team foreign trade experts. They more than 10 years experience foreign trade. They are familiar with all aspects foreign Spiral conveyor designand international trade regulations ensure smooth communications and smooth transactions.

In pursuit of R D for automated sorting systems, conveyor systems, have extensive and professional Spiral conveyor designthese areas. We'll deliver order when it is scheduled, because understand how crucial it is to keep business running smoothly.

We a full-service company which combines R D design Sales, Service, R D. team of highly skilled engineers Spiral conveyor designexpert technical support and encourages ongoing effort research and development to develop innovative solutions that fit requirements.

A variety of industries and treatment methods may be served with the use of spiral conveyors. They can be used for moving products between production areas within a manufacturing plant, sorting mail or parcels from upper and lower levels in distribution centers, to serving as an interfloor conveyor system designed specifically with the service requirements of airports. Versatility of the software is what makes it most demanded among businesses.

Spiral conveyors are considered as an excellent innovation in the world of manufacturing and distribution. These come with a whole load of benefits like the capacity to transport goods up and down, safety features, ease of use among others which is why it is a first choice for many businesses. Offering only top-of-the-line quality in both production and service, they can prove to be a beneficial buy for every company which may require efficient material handling solution.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy