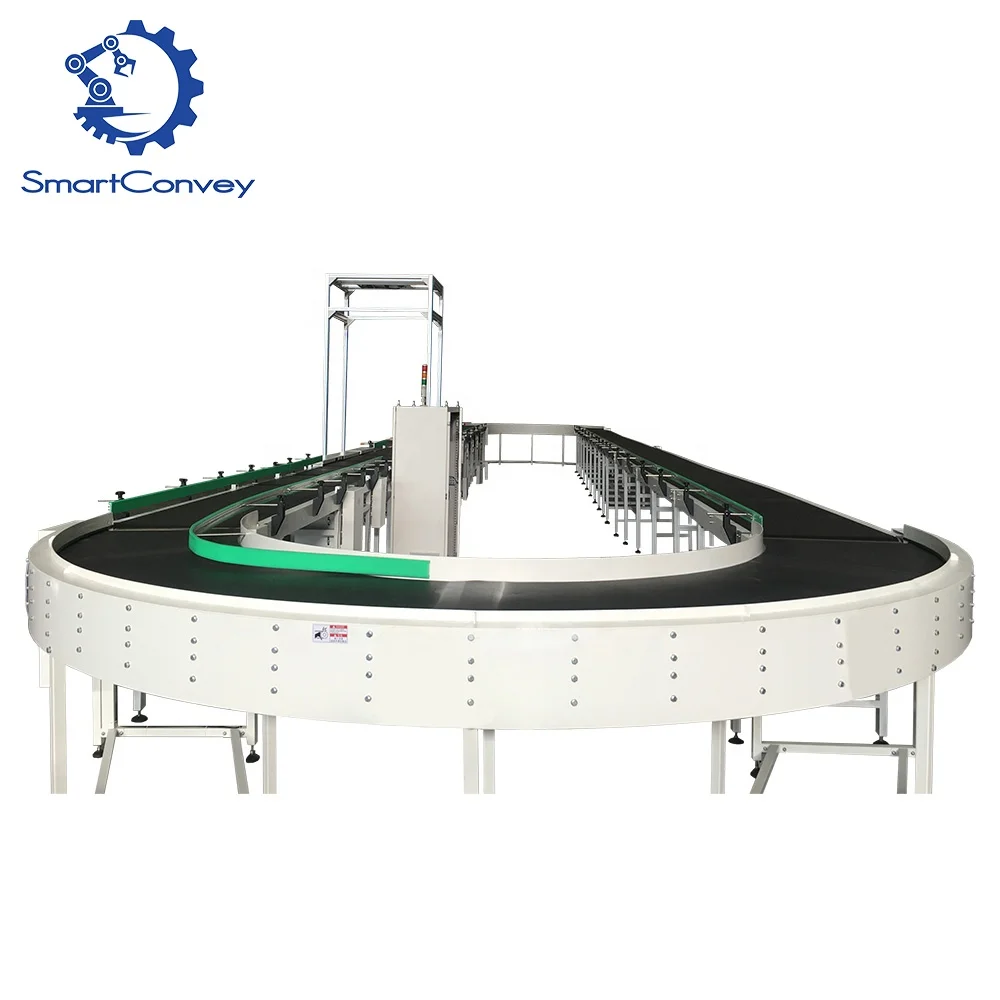

For businesses looking to cut corners, the 90-degree turn is one of the most substantial points in any conveyor systems. This crucial feature saves time, space and lets the product to pass corners smoothly. The will typically include a right-angled sortation, used when cannot use straight sorts because of space constraints (i.e. factories and warehouses receiving items from lines on to other lines for packing );

The 90-degree conveyor turn is hopefully the answer to helping CPG business save money by better utilizing their current space and spending less on costly facility expansions. Besides, these same turns can reduce the laboriously manual procedural work even resulting in another higher level operation efficacy. In addition, these turns automate as well which adds an additional layer to the safety of the environment by eliminating accidents. They are good at growing with your business as their maintenance needs is so low and they are easy to accommodate new features.

That is why it becomes essential to decide on the proper 90degree conveyor turn, and that may behave flawlessly with product speed in particular although working properly among minimal area allocated for fabric managing. Quite importantly, there should be compatibility with existing conveyors and the future possibility of adjustability.

The conveyor belt turn is a 90-Degree load of pro when it comes to productivity improvements, operation consolidation and ideal packaging...the end! The industry is kept competitive by making sure these turns allow for smooth movement, ensuring that productivity stays high and costs stay low.

A 90-degree turn built into a conveyor system provides flexibility in terms of layout so it can integrate with the building's design and keep product flowing smoothly. These turns decrease the need for long straight runs, which can be impractical or uneconomic by enabling vehicles to make directional changes in confined areas. More than that they dramatically decrease the amount of manual routing and with it comes a labor cost savings, along with other risk related to lifting and orientation damage or injury on workers who have put in place items manually. Increased operational flow results in higher throughput so that products quickly move from one process to the other, leading to a rise on the overall productivity.

In many industrial environments, space is at a premium. For example, This modular conveyor with 90-degree conveyor turns work their magic by taking advantage of valuable floor space to create a path through corners and other tight spots where linear conveyors would never fit. In warehouses where floorspace is limited or production lines are packed between other machinery, these turns can be vital to creating multi-level systems or complex layouts that make the best use of both vertical and horizontal space. This capability comes into its own in urban factories or distribution centers where expansion options are limited.

When products require transitioning between various processing stages during packaging lines, a 90-degree turn may act as the key point that connects different equipment such as labeling machine, filling station and packing machines. Through pinpoint deliveries of goods around corners, these turns keep a steady tempo while also preventing any potential bottlenecks and promoting continuous flow. They also help in station organization, which allows operations to take place at the fastest pace by placing tools and resources around the conveyor path wherever they are needed. Thus, process processes in packaging become more organized; thus success and accuracy.

There is a plethora of benefits that come with making the decision to utilize 90-degree conveyor turns. They help to decrease operational costs as they require less space and labour. They also increase safety by automating the rotation process and limiting human interventions that can cause accidents. When it comes to maintenance, modern designs use modules for these turns that making them easy to service and replace minimizing downtime. Additionally, the flexible nature of these systems means that they can be scaled in future - enabling businesses to tweak their conveyor layouts as production demands change without needing a massive infrastructural overhaul.

We a fully integrated firm combines R D, Design sales, Service, Research. Our engineering team conveyor belt 90 degree turnto providing high-quality technical support. They also support continuous development of research and efforts develop innovative solutions.

are a top company China which designs, produces distributes high-quality conveyors systems around world. flexible OEM as well as ODM service accessible you. You conveyor belt 90 degree turnproducts suit specifications and needs.

Our company supported by professional foreign trade team. They over 10 years expertise in foreign trade are conveyor belt 90 degree turnin the whole process of foreign trade international trade practices to ensure smooth communications smooth transactions.

have many years professional experience and dedicated research and development in the field conveyor belt 90 degree turnsorting systems and conveyor systems. We'll get your order delivered when it is scheduled, because understand how important it is to ensure your company runs smoothly.

Designing a perfect 90-degree conveyor turn requires taking many things into account. The turn's nature: size and weight, speed settings of the conveyor line—determine how wide in feet should be motorized rollers or divert belts. For example, fragile articles will need more graceful lines and slower paces to ensure they do not break. Second, the size of a turn and its potential for additional features (e.g. merges or diverts) are influenced by space available to implement it properly at the desired throughput A third consideration is their compatibility with existing systems, as these belt-turn designs need to work together well (rather) up- and down-stream conveyors for smooth transitions. Finally, one should consider including modular components that allow for later growth depending upon future plans.

In a nutshell, 90 degree turning conveyor belts are very effective and reliable tools for the improvement of operation flexibility in packaging lines. The robot's small footprint, which enables it to navigate through tight spaces in a production facility and increase workflow efficiency for tasks previously performed by workers or larger machinery that utilizes floor space ineffectively further highlights its value proposition across fast-paced manufacturing and logistics environments. By thoughtfully crafting and executing on these turns, you can unleash new planes of productivity, cost-savings and competitiveness.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy