Ideal for Automated Pallet Conveyor Systems

Ever thought what keeps movements within a warehouse or factory? The traditional way is that you have to lift and store them with the help of hand trucks, forklifts. But as the years have pasted, technology has been continuously evolving that commercialization of automatic pallet conveyor systems really changed the scope of things to be moved. This approach not only improves efficiency but also covers safety at the job site. Here we will explore different dimensions of Automated Pallet Conveyor Systems & why they matter in modern industries

Automated pallet conveyors have many benefits. These systems are uniquely built for their speed, efficiency and high productivity levels compared to traditional methodologies. Conveyor belts are used to quickly move materials through the production process and lessening deficiencies in manpower. These are pallets of different sizes and loads (per load per 50 to about 2000lbs) that serve as transportation or From one area in the warehouse,minimized only with two system.

Industries were enamored by this newfound ability to automate, and so the topography of automation within industries began to change rapidly over these years; ushering in next-gen products. An example of such innovative solutions is automated pallet conveyor systems. Single and double deep pallet storage systems - these solutions use the latest technology to ensure that pallets are moved with precision, thereby reducing human error. This not only reduces the production time but also improves quality control, which then leads to more product output.

No matter what the work, worker safety is one of utmost importance in any job situation. The automated pallet conveyor systems are very sophisticated as well in the sense they make it difficult for accidents to occur. These operational systems help to prevent any manual labor which would harm the workplace safety of workers. Human error and accidents are minimised through the decrease of human conducted actions.

Automated Pallet Conveyor Systems Ease of operation:

Automated pallet conveyor systems are easy to operate. There is a time required to get things set up initially but once they are all in place, its fairly easy going from there as far management of the systems. These conveyors are provided in different sizes, and can be personalised to meet your specific needs. Operators just have to place the pallet on the conveyor, and rest will be taken care of by Automated Guided Vehicle Systems which makes transportation process more efficient.

Guidelines for Using Automated Pallet Conveyor Systems:

Designing And Implementing Automated Pallet Conveyor Systems-10 Tips For Success The stability and security of the package is number on as you first point. When this is confirmed, the pallet will be transported along the conveyor to its predetermined location. Operators control the speed and direction of the conveyor to guide product through standardized workflows in each warehouse or peak season spaceregardless.

Restoring automated pallet conveyor systems to top efficiency needs routine upkeep. Checking the system for signs of wear is important as it can help extend its lifespan. The companies that supply these systems typically offer maintenance services, or else in-house maintenance teams can be trained to make any repairs needed effectively.

Quality and Durability:

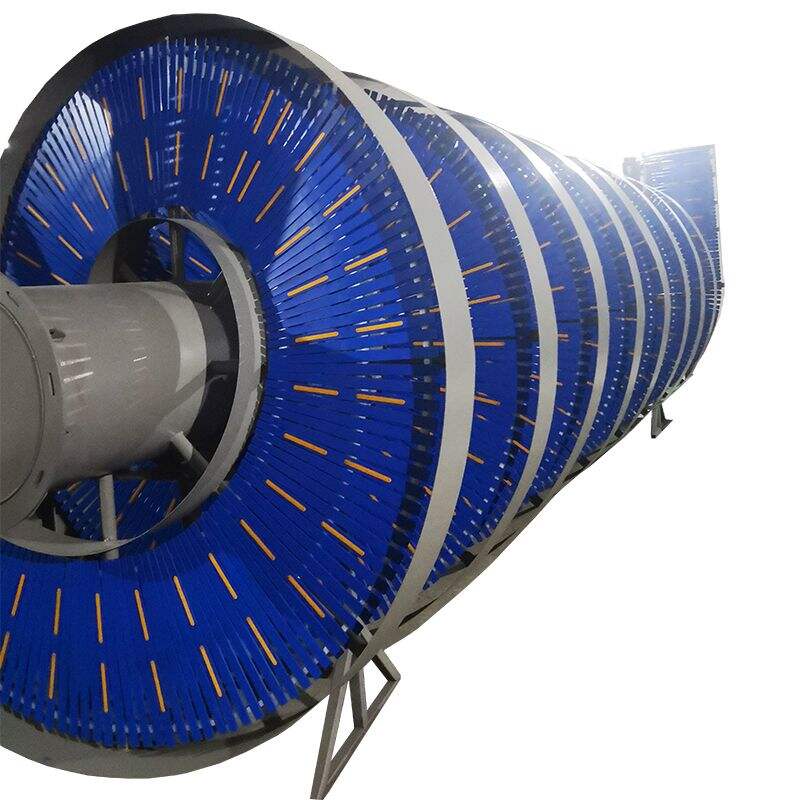

As well as being incredibly durable and long lasting, automated pallet conveyor systems are designed specifically for the demands of industrial environments. Coupled with regular servicing, these conveyors are able to handle thousands of pallet loads and if looked after properly, can last for more than 25 years - a sound investment for any business.

company staffed by a highly skilled team foreign trade automated pallet conveyor systems. They have over 10 years working in the field foreign trade. They proficient in the entire process international foreign trade procedures to ensure smooth communications and smooth transactions.

We a multi-faceted company consisting comprising R D design sales, automated pallet conveyor systems. team of highly skilled engineers provides expert technical support encourages ongoing research and development create innovative solutions that fit your needs.

We committed research and automated pallet conveyor systemsof intelligent sorting systems, conveyor systems, have rich and extensive experience these fields. We'll ship your order according to time frame you have set because we know importance of it to keep your business running smoothly.

We top company in China designs, produces sells top-quality conveyor systems throughout world. flexible OEM as well ODM service accessible you. Make products custom-designed automated pallet conveyor systemsyour requirements and needs.

Automated pallet conveyor systems have a very wide range of uses in manufacturing industries, retail and wholesale trade. They can be adapted and customized to fit the requirements of companies both large and small, managing tailored operational needs with simplicity.

To the ends of it in conclusion, automatic pallet conveyor systems are on top with respect to changing trends material handling strategies across a broad spectrum regarding manufacturers. The problems of manpower, safety concerns and the time delay have been resolved or improved considerably by their speed/speed efficiency ratio as they expedite a series on manual labors at this juncture with increased operational safety. These systems are easy to use, and require very little training for implementation by a variety of users. With regularly maintenance, businesses can enjoy years of reliability and make automated pallet conveyor systems to be an essential element in material handling that we know today. Their wide applications proved their flexibility and versatility, indicating that they will become the pillars of future material handling solutions in the industry.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy