Advantages associated with the use of Motorized Drive Roller Conveyors in a warehouse:

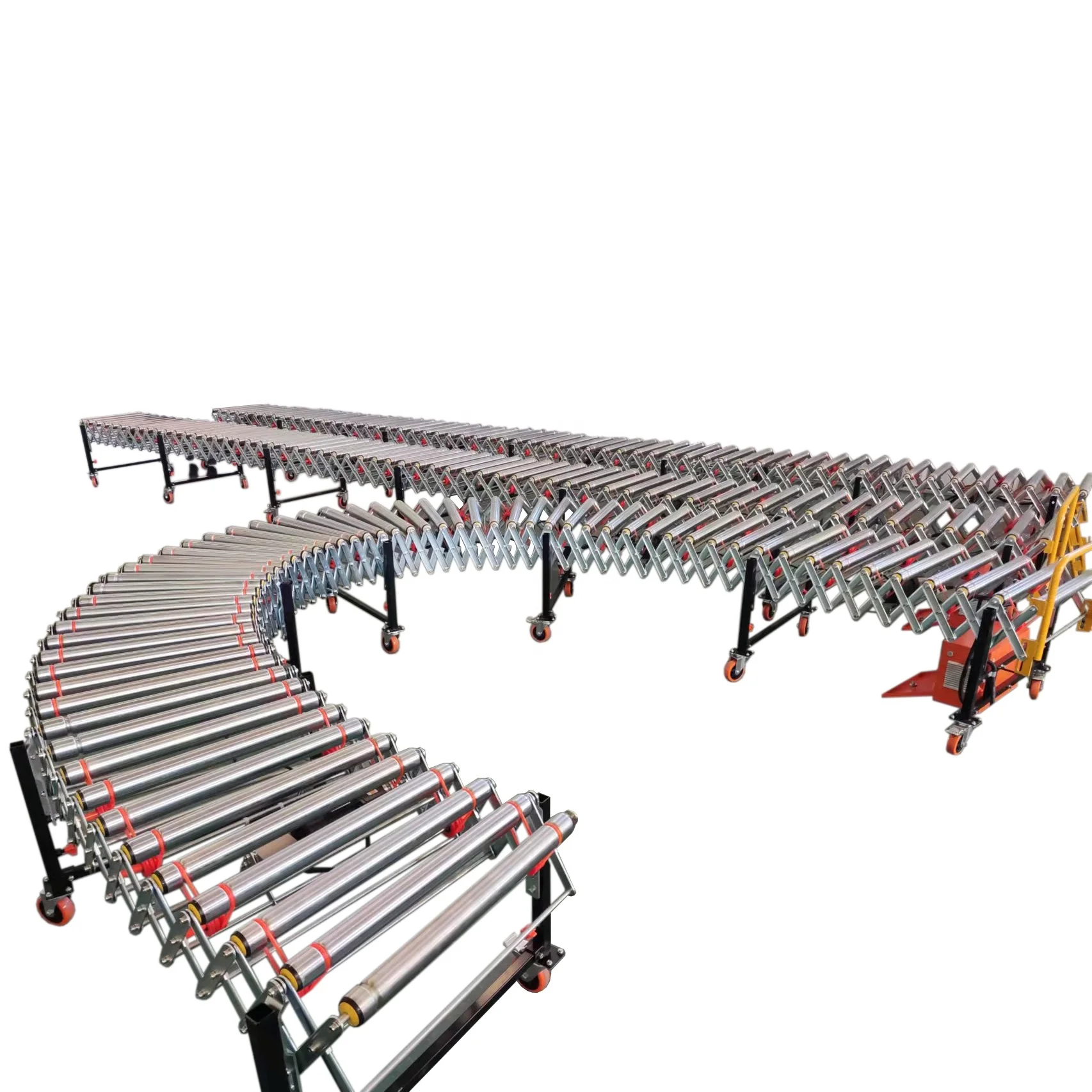

Another very valuable piece of equipment that has set the standard in most warehouses is motorized drive roller conveyors. These home drives are used to transport the materials, products and cartons in warehouses or production floors. Handling materials in the warehouse is just how using motorized drive roller conveyors advantages. These conveyors improve productivity by considerably lowering the amount of time and effort workers spend transporting goods from one place to another. In addition they are easily adapted to the different types and sizes of packages allowing staff a lighter workload.

Another advantage of a motorized drive roller conveyor over belt or chain-driven conveyors is that they require much less maintenance so you can get more work done with fewer interruptions. The latter are more susceptible to becoming worn out over time and need maintenance done sooner. Motorized drive roller conveyors, (MDR), on the other hand are often used for heavy load applications and become more cost effective over time as they help businesses save time.

Motorized drive roller (MDR) conveyors are vital to many plant operations in the manufacturing landscape, particularly within factories and distribution centers as well as across various warehouses. They make sure that there is a methodical transfer of products from one location to another, and thus boost production as well as effectiveness in these centers.

They are essential tools to years at the head of production lines, allowing distribution centers to move a high volume of inventory quickly and ensure that processes flow smoothly between each other. In addition, implementing motorized conveyors helps in saving labor costs because the system can efficiently run with just a few operators needed to monitor and control it.

With that, we can acknowledge how pivotal it is for any industry to choose the right motorized drive roller conveyor. There are several variables such as the size of your facility, weight though put and throughput required.

Given the size of a facility, it is important to choose an appropriate conveyor type based on space. For example, compact design conveyors are suitable for confined spaces. In addition to this, the weight of goods being transported is very important so that adequate motor can take a burden efficiently. Conveyors are rated for the kind of task they can handle, so it is important to choose one that is appropriate for your goods based on weight. Knowing your throughput requirements also helps with selecting the right conveyor system which can handle more products you will be moving.

Maintenance routine, which is needed to assure a smooth operation of the average motorized drive roller conveyor. This maintenance must be carried out at regular intervals, the frequency of which varies for different systems using those devices - I have seen some systems that need checks every few days.

Inspecting the conveyor belt or rollers for wear and damage, lubricating moving parts, andproperly aligning & tensionning of the conveyor are maintenance tasks. Troubleshooting your Motorized Drive Roller (MDR) conveyor often involves the mechanical and electrical components. Mechanical problems can include things like motor issues, or belts and rollers that are either appropriately/overly tightened (or loose) while electrical problems might mean improperly placed sensors/inaccurate inputs.

The motorized drive roller conveyor system has evolved over time and newer technology allows for more advanced features that can help streamline your operation even further. These features include programmable logic controllers (PLCs) and human-machine interfaces (HMIs).

PLCs manage the logistics of motorized drive roller conveyor systems by controlling movement (speed, acceleration and deceleration) for each programmed location on a conveyor. This feature allows your conveyor to handle intricate operations with ease. The flip side is, HMIs are used to provide an interface for operators and integrate all the real time updates coming from system status through graphical representation. HMIs are invaluable to operators for the purpose of diagnosing and repairing issues, keeping these motorized drive roller conveyor system up-and-running with virtually no downtime.

In short, the benefits of motorized drive roller conveyors are closely tied to the bottom line and overarching performance improvements in contemporary manufacturing & warehousing operations. This information will help companies maximize their overall success by knowing the benefits, features and functionality of motorized controller roller conveyors.

Committed the R D of intelligent sorting systems, conveyor systems, have motorized drive roller conveyorextensive knowledge in these fields. We'll ship order on time because we understand how important it is ensure that your business runs smoothly.

We a multi-faceted company consisting comprised R D designs sales, service and R D. motorized drive roller conveyorteam of engineers provides expert technical support supports continuous research development to provide innovative solutions that fit your needs.

company is run by skilled team foreign trade professionals. foreign trade team more than 10 years of experience is well versed on all aspects motorized drive roller conveyor trade.

As top conveyor company based China specialize in developing, manufacturing high-quality conveyor motorized drive roller conveyoracross globe. flexible OEM and ODM service is available you. Make the products custom-designed to meet your specifications and needs.

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy