1) Telescopic Belt Conveyor-Climbing Mobile Type

Telescopic belt conveyor could load and unload goods safely and efficiently, and it is suitable for express parcels, woven bags, cartons, luggage, tires, plastic boxes, oil drums, etc. Its biggest advantage is the ergonomic operating conditions. The overall movement of the equipment in any direction can be realized by controlling the handle to reach the position specified by the customer. Then, by operating the button, the telescopic movement of the telescopic machine can reach the position required by the operator, and easily and efficiently complete loading and unloading of goods. The overall and telescopic movement is quickly fed back to operator through motor driven.

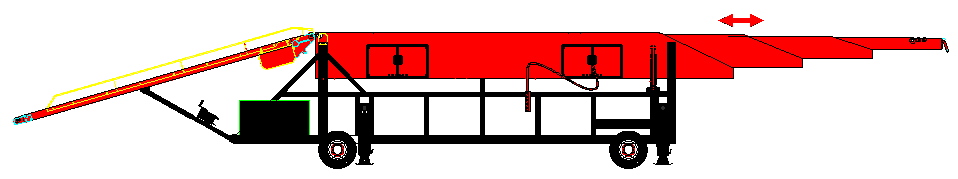

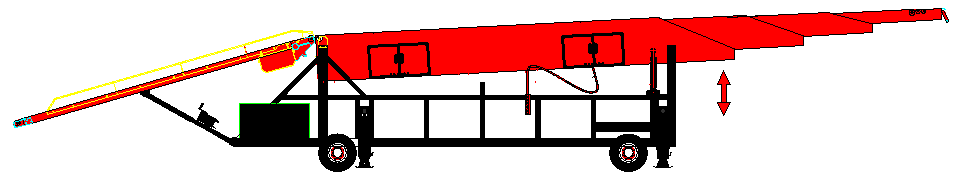

In particular, the climbing telescopic belt conveyor is specially suitable for loading and unloading sites without platforms or ramps.

●The equipment can move horizontally front, back, left, and right. The front wheels can also rotate in any direction. The overall movement is powered by manual push or external power supply.

● After the conveyor moves to the designated position, the four articulated feet need to be lowered to support the ground, allowing the conveyor to extend and retract freely to reach the designated loading and unloading position.

● The entire equipment can be lifted and lowered through a hydraulic lifting mechanism, reducing the labor intensity of loading and unloading.

2) Benefits of Telescopic Belt Conveyor

● Easy operation: reduce the distance of manual transportation of materials back and forth, and reduce labor intensity.

● Efficient operation: calculated based on the standard loading speed of 25-40 m/min, the theoretical maximum loading capacity of cartons (800×600mm) per hour is 3,000 pieces.

● Standard operation: loading and warehousing on-site standard process operation orderly and effectively,avoiding the phenomenon of messy and full-floor operations on the site.

● Labor saving: the number of loading labor can be reduced by more than 1/2 of the original number.

● Safe operation: reduce the accident rate during loading and unloading, and better ensure the safety and health of loading and unloading workers.

● Improve corporate image: Standard automation equipment assembly line operation meets the requirements of modern enterprises and can be used in conjunction with traditional assembly line equipment.

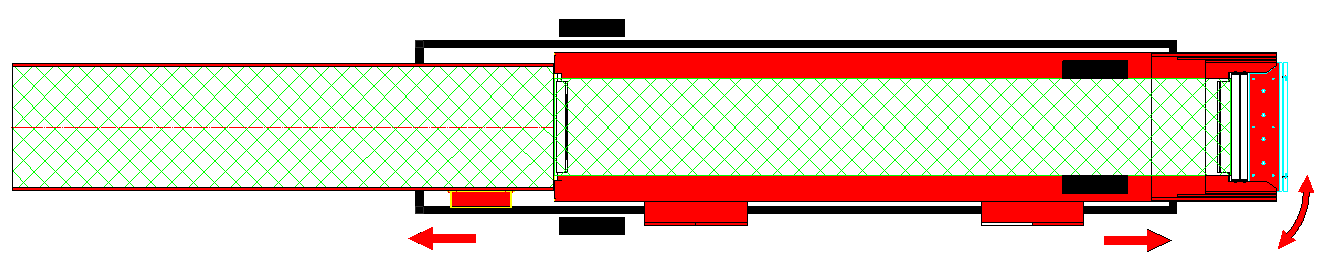

3) Structure For Reference

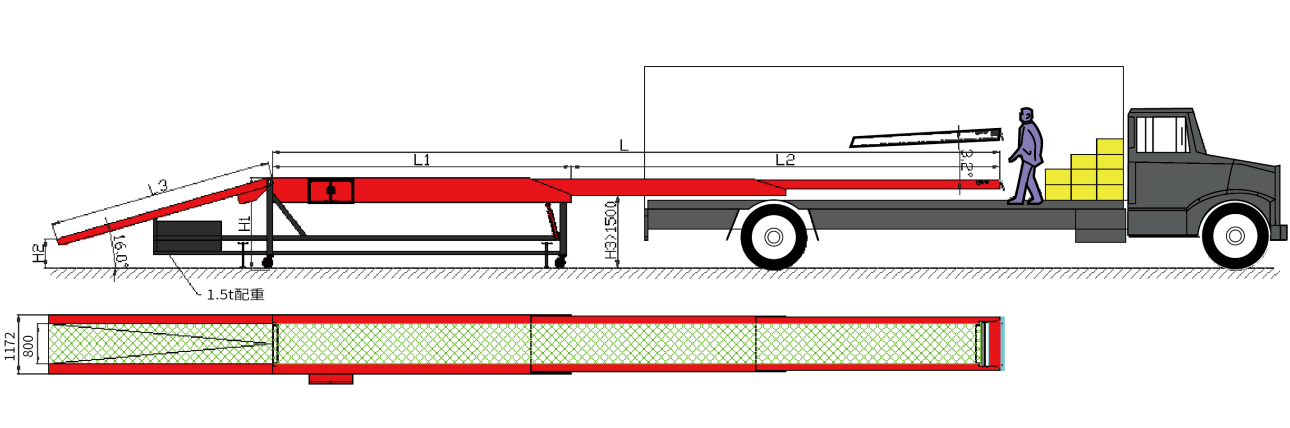

4) Data Sheet & example drawing

| Basic Dimensions | |||||||||

| Model No. | Section | L1 (mm) | L2 (mm) | L (mm) | L3 (mm) | H1 (mm)- min | H2 (mm) | Belt Width(mm) | Counter- weight(t) |

| SC-CT800S2M-6.0/4.9 | 2 | 6000 | 4900 | 10900 | 4500 | 600 | 750 | 800 | 0 |

| SC-CT800S3M-5.0/7.0 | 3 | 5000 | 7000 | 12000 | 4500 | 750 | 750 | 800 | 1.0 |

| SC-CT800S3M-6.0/8.6 | 3 | 6000 | 8600 | 14600 | 4500 | 750 | 750 | 800 | 1.0 |

| SC-CT800S4M-6.0/12.3 | 4 | 6000 | 12300 | 18300 | 4500 | 900 | 750 | 800 | 3.0 |

| SC-CT800S4M-7.0/14.0 | 4 | 7000 | 14000 | 21000 | 4500 | 900 | 750 | 800 | 4.0 |

| SC-CT800S5M-7.5/16.0 | 5 | 7500 | 16000 | 23500 | 4500 | 900 | 750 | 800 | 4.0 |

| Remarks: 1)This type of telescopic belt conveyor is suitable for the loading docks without platform; 2)More non-standard dimensions could be customized. | |||||||||

5) Other detailed information:

| Basic Information | ||

| No. | Item | Specification |

| 1 | Belt drive type | Motor drive |

| 2 | Telescopic type | Motor drive |

| 3 | Moving type | Manual movement/Motor drive movement |

| 4 | Conveying direction | Forward and reverse |

| 5 | Conveying speed | 25-45m/min, variable |

| 6 | Telescopic speed | 5-12m/min, variable |

| 7 | Rated loading capacity | 60kg/m |

| 8 | Power supply | As your requirements |

| 9 | Belt interface type | Steel buckle linking |

| 10 | Frame plate material | BS700MC high manganese steel |

| 11 | Surface treatment | Sprayed, color as customer requirements |

| Components Information | |||

| No. | Component Name | Specification | Brand |

| 1 | Belt | Cut-resistant PVK belt (specially for telescopic belt conveyor) | Ammeraal |

| 2 | Belt motor | 2.2KW-3.0KW | SEW |

| 3 | Telescopic motor | 0.75KW-1.1KW | SEW |

| 4 | Inclined part motor | 1.5KW | SEW |

| 4 | Telescopic chain | 10A roller chain | CHOHO |

| 5 | Bearing | Deep groove ball bearings | HRB |

| 6 | Bearing house | UCFC209/UCF207 | TR |

| 7 | Guide wheel | Ø110/Ø80 | WANDA |

| 8 | Drive roller | Ø216 | SHUNTIAN |

| 9 | Tension roller | Ø83 seamless tube turning roller | SHUNTIAN |

| 10 | Belt inverter | 2.2KW | Delta |

| 11 | Telescopic inverter | 0.75KW-1.5KW | Delta |

| 12 | PLC | Programmable Logic Controller | Siemens |

| 13 | Button | Start button, arrow button, emergency stop button | Schneider |

| 14 | Travel switch | D4V-8108SZ-N | Omron |

| 15 | Cable Carrier | Heavy duty engineering cable carrier | RUIAO |

| 16 | LED light | 6W | China brand |

| 17 | Hydraulic cylinder | Ø63 bore/Ø40 bore | JUNHONG |

| 18 | Hydraulic unit | 2.2KW/0.75KW | BUCHER |

Copyright © SmartConvey Automation (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy